In order to address the needs of warehouse facilities, support operations of integrated LSPs and independent warehouse operators, Trejhara has created an integrated Warehouse Management System (WMS) which comprises various modules that can be independently deployed.

The primary purpose of a WMS is to control the movement and storage of materials within an operation as well as to process them for transactions, picking, replenishment and putaway. Trejhara’s WMS offers functionalities that manage simple and specialized warehouses.

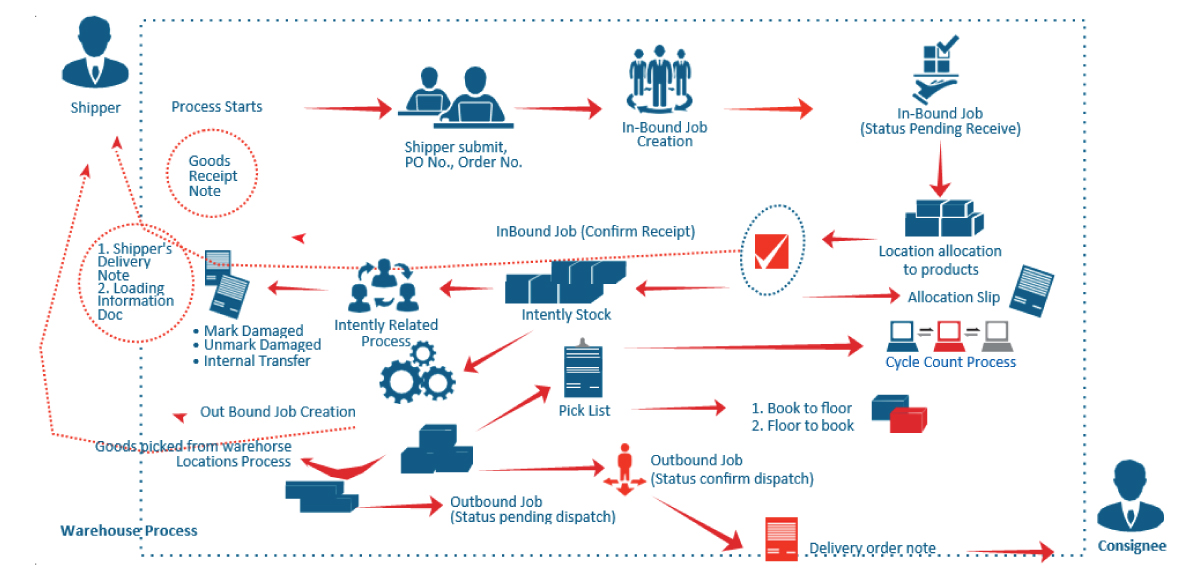

It helps ensure fast, accurate fulfillment through directed workflow. The system executes processes such as receiving inbound transaction, put-away/flow-through and inventory management apart from internal processing like cycle count, internal transfers, changing goods’ status, pickup for outbound loading & shipping, statistical & management reports, quotation & billing, and customer tracking for visibility & search functionalities.

General

Inbound

Contract & Billing

Mobility

Outbound

Other Warehouse Operations

Productivity Tools